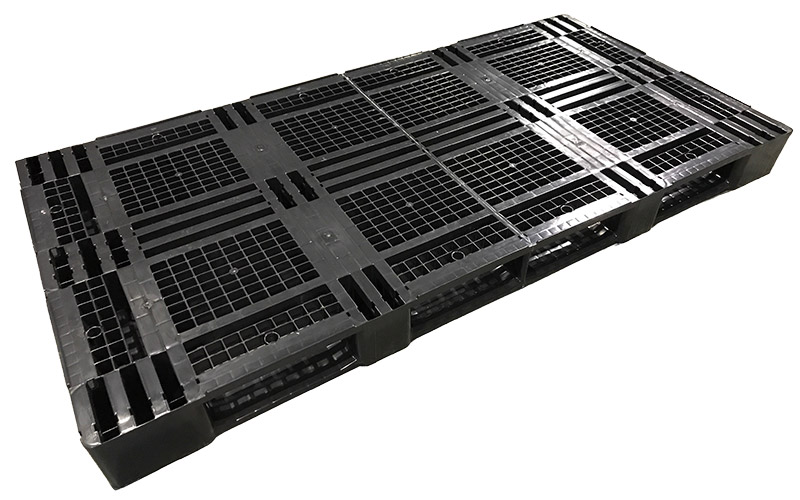

Megafab designs and fabricates oversized plastic pallets tailored for heavy-duty materials handling across UK and European industries. Ideal for oversized components, heavy loads, or machinery, our pallets provide exceptional load-bearing capacity, durability, and compatibility with automation systems - without the drawbacks of wood or steel.

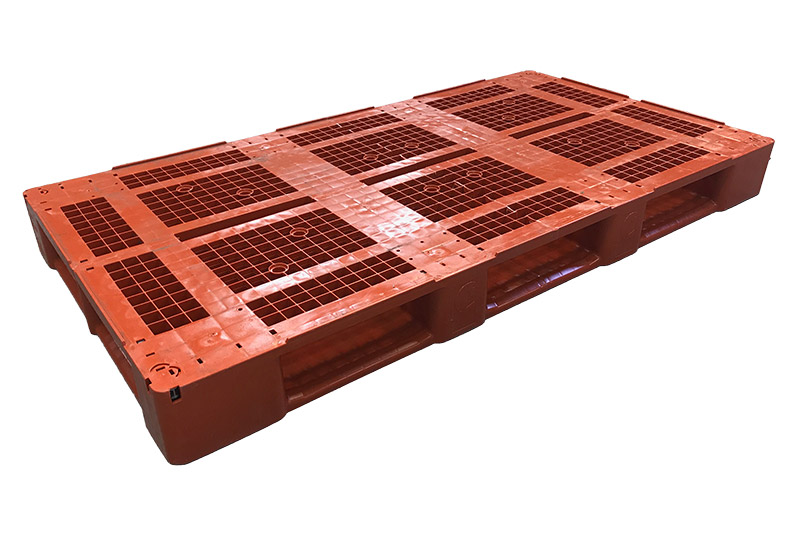

Every pallet is engineered to meet your exact dimensions, weight loads, and handling equipment requirements. Using reinforced welding, precision machining, and top-grade HDPE or PP, our oversized pallets deliver repeatable performance in high-volume logistics, manufacturing, and closed-loop supply chains.

Custom‑Size Pallets Built to Your Specification

From bespoke dimensions to heavy load performance, we build oversized pallets around your operational needs, providing engineered solutions for extra length, width, or load capacity. All fabrication is handled in-house to ensure tight tolerances and fast delivery.

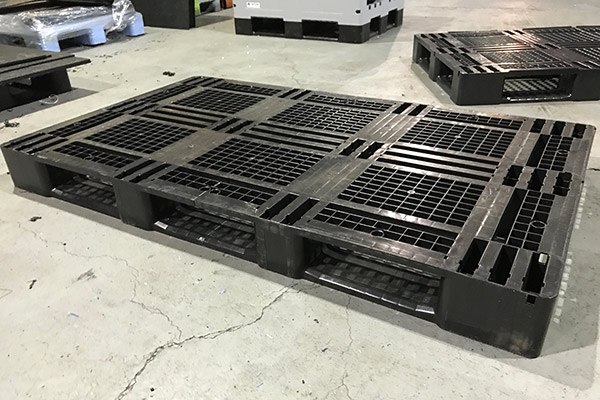

Structural Reinforced Oversized Pallets

Megafab builds pallets engineered to handle large, heavy, or awkwardly shaped loads with ease and reliability.

- Construct pallets to bespoke dimensions—length, width, height and profile

- Reinforce decks and runners using thick plastic sheet and welding

- Integrate steel inserts or ribs for added strength if needed

- Include anti-slip top surfaces or friction runners for grip

- Deliver pallets with precise weight/load ratings for safety compliance

These pallets are built to last, resist deflection, and withstand repeated forklifting and stacking cycles in industrial use.

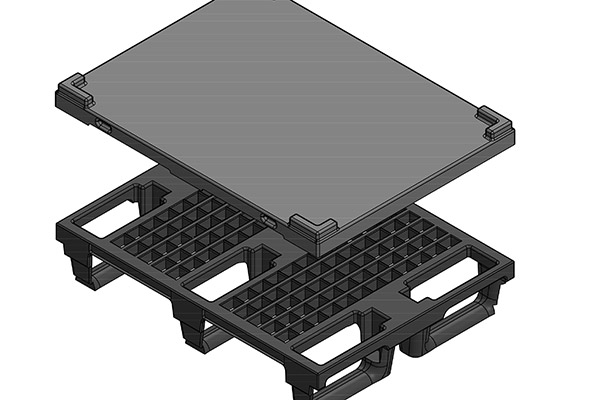

Automation Friendly & Racking Compatible Designs

We ensure oversized pallets work seamlessly within your handling systems, conveyor, automated lines or racking.

- Design for 4‑way entry, side lift, or drive‑in racking use

- Machine cut entry notches, grip cut‑outs, and EVS access

- Supply nestable or rack‑stacking pallets for efficient storage

- Include RFID pockets, pallet lids or collars for protective handling

- Colour‑code runners and handles for line‑specific control

Our pallets are engineered to fit into your logistics flow so that no custom mounting or manual adjustment is needed.

Built to Withstand Real Workloads

Megafab’s oversized plastic pallets are actively used in:

- Solar panel and glass component handling

- Automotive and aerospace assembly line logistics

- Heavy machinery and plant parts storage

- Manufacturing and process line transport

- Closed‑loop pallet pooling systems

We build each pallet to operate in high-turn, high load settings - ensuring consistent performance, stability, and safety.

Precision Moves with Every Lift

Ensure your pallets move smoothly with design tuned to your handling equipment and environment:

- Runners and decks cut for stable stacking and nesting

- Optional castors, skids or corner lift pockets included

- Smooth or anti‑skid decks depending on load type

- Dimensions exact for conveyor, rack, or forklift fit

- Handles or grip points for safe manual handling

Your workflow determines the specifications our pallets are engineered to fit. No workarounds, no compromise.

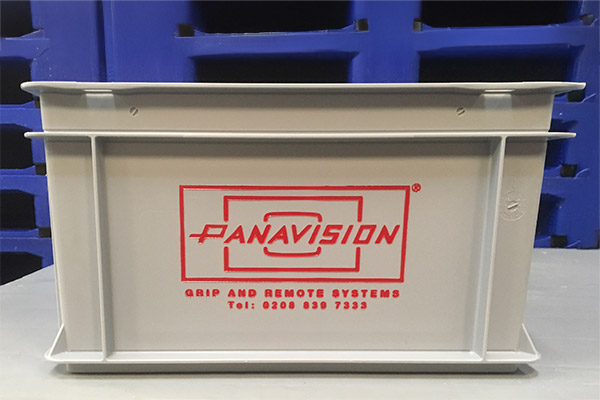

Engineered for Traceability

We add finishing touches that support logistics control, safety and asset management:

- Hot foil stamping for serial numbers, logos, or load specs

- Colour-coded decks and runners for line or product ID

- Optional metal or RFID tracking inserts

- UV stabilisation and chemical-resistant materials

- CAD files and documentation for system integration or repeat ordering

Megafab pallets are built for long term use, traceability, and visibility in any industrial system.