At Megafab, we provide expert plastic welding services for the materials handling industry. Using both conventional plastic welding and extrusion welding, we deliver strong, durable joins for crates, pallets, storage boxes, and custom components. Whether you need precise modifications or heavy-duty structural welds, our solutions are engineered for long-term industrial performance.

Our Plastic Welding Capabilities

Our in-house welding expertise covers proven techniques, giving you flexibility across project types and component sizes.

Conventional Plastic Welding

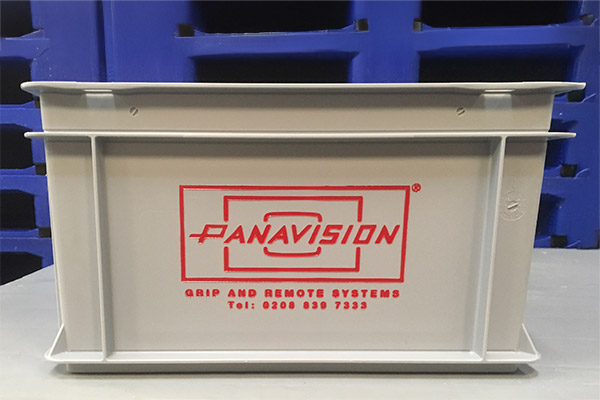

Conventional plastic welding is the go-to method for precise, reliable joins in small to medium components, or where modifications and repairs are needed. By using techniques such as hot air welding, hot plate welding, and filler rods, we can adapt or restore crates, pallets, and storage boxes with a strong, neat finish.

-

Seam welding for crates, lids, and storage boxes

-

Edge repairs and reinforcements on existing units

-

Joining thinner sections or complex shapes

-

Controlled heat input to minimise distortion

-

Clean, uniform welds suitable for visible surfaces

This method is ideal for detailed work and modifications where accuracy and appearance matter.

Extrusion Welding

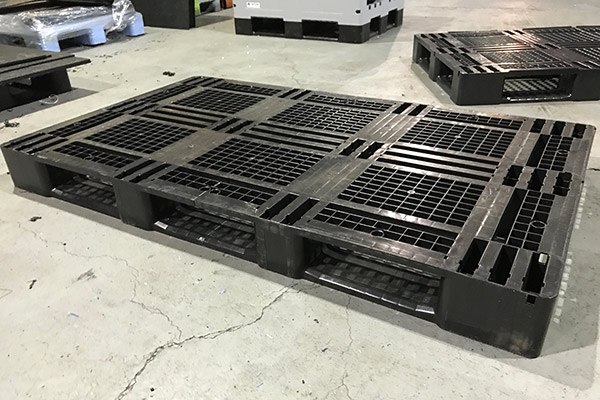

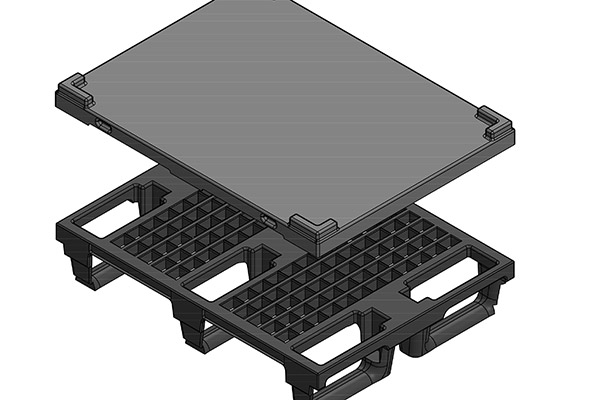

Extrusion welding is a high-strength process designed for joining thicker plastic materials and building larger components. By heating surfaces and applying molten filler material under pressure, this technique delivers structural integrity for oversized crates, pallets, and industrial storage solutions.

-

Strong welds in panels and sheets over 6 mm thick

-

Butt, T-joint, overlap, and groove joint capabilities

-

Structural welding for oversized boxes and pallets

-

Continuous filler application for consistent results

-

High-strength bonds suited to repeated heavy use

This method is the preferred choice for large-scale projects that demand strength, durability, and long service life.

Built for Industrial Use

Megafab’s welded components are designed to perform in tough environments, including:

-

Warehousing and automated handling

-

Manufacturing and assembly plants

-

Closed-loop logistics systems

-

Bulk material storage and recycling operations

-

Secure transport and return packaging

Every weld is engineered for durability, ensuring your products last longer and perform reliably.

Scalable Supply for Custom Projects

From prototypes to production runs, our welding services scale to fit your needs.

-

Low-volume runs for one-off modifications

-

Medium batches for specialist applications

-

High-volume production for standard fleets

-

Flexible turnaround to match your schedules

-

Consistent UK-based quality across every unit

Whatever the order size, you can rely on Megafab for precision and repeatability.

Engineered Plastics for Form and Function

We combine welding expertise with high-performance engineered plastics to create products built for industrial demands.

-

Compatible with PE, PP, PVC and other thermoplastics

-

UV- and chemical-resistant options

-

Smooth welds for hygiene and cleaning

-

Compatible with automation systems

-

Custom finishes for branding or compliance

The result: products that are strong, reliable, and designed for long-term use in demanding applications.