Megafab delivers high-precision CNC machining, cutting, and routering for plastic components and handling systems across the UK and Europe. Whether adapting off-the-shelf crates or producing fully customised inserts, we help industrial clients enhance performance, compatibility, and efficiency in materials handling environments.

Our Plastic CNC Machining Capabilities

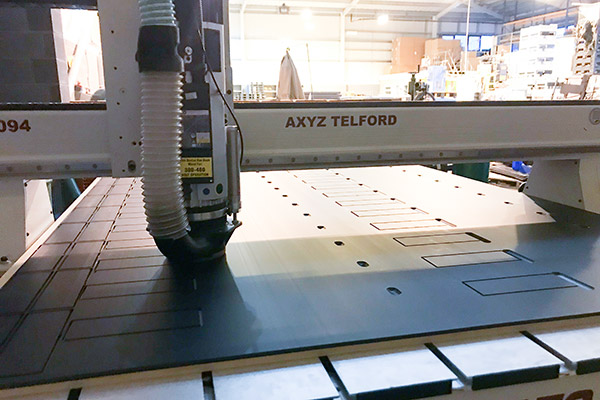

Megafab operates three advanced 3-axis Trident CNC routers, enabling high-speed cutting, profiling, and routering of plastic panels, boards, and components with consistent precision. Our UK-based CNC machining services are designed for industrial users who need reliable, customised plastic fabrication. We deliver complex shapes, drilled features, and tailored adjustments with speed and accuracy, supporting everything from one-off prototypes to high-volume production. Additional options include castor fitting for mobility, metal inserts for added strength, and dividers or foam inserts for product protection. With hot foil printing available, we ensure your plastic parts are durable, functional, and ready for demanding industrial environments.

Precision Modifications to Existing Products

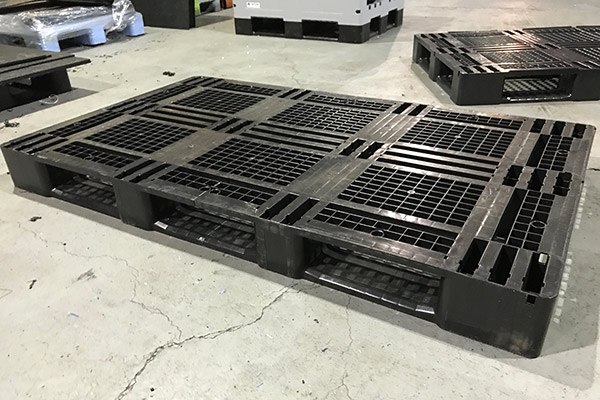

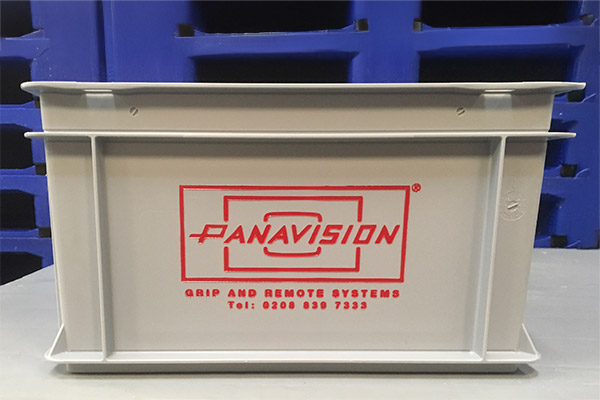

Using CNC machining, we adapt standard crates, pallets, and lids into application specific solutions:

- Add ports, handles, drainage slots, or cable entries

- Drill mounting holes for hardware, sensors, or internal fittings

- Cut recesses for tags, locks, or metal inserts

- Trim oversized panels or profiles to tolerance

- Ensure repeatable machining across all units

- Every part is measured and checked for consistency, durability, and ease of integration.

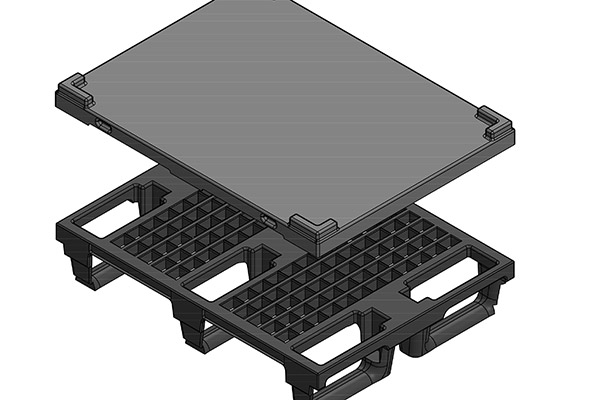

Custom Components from Plastic Sheet

We CNC-machine parts directly from sheet or plate material to suit your exact operational needs:

- Build dividers, covers, lids, and fit-to-purpose inserts

- Router panels with slots, grooves, or milled edges

- Create lightweight or impact-resistant assemblies

- Use static-safe or reinforced plastics as required

- Deliver matched sets or one-off prototypes

Each part is cut to integrate seamlessly with crates, containers, or custom handling setups.

Built for Industrial Use

Our CNC-machined plastic components serve demanding environments like:

- Automation and smart warehousing

- Materials handling and logistics

- Manufacturing and assembly plants

- Closed-loop supply chain systems

- Technical packaging and protective housings

Each item is engineered for strength, repeatability and trouble free performance in tough conditions.

Fast Turnaround & Scalable Output

Megafab’s in house machining setup is designed for industrial speed and flexibility:

- Rapid prototyping and quick changes

- Medium-volume production with consistent output

- Tight tolerances and finishing standards

- Integration with our welding, forming, and fabrication services

- Lead times aligned to project scope and urgency

Whether you’re developing a new system or modifying a legacy one, Megafab delivers components at pace and to specification.

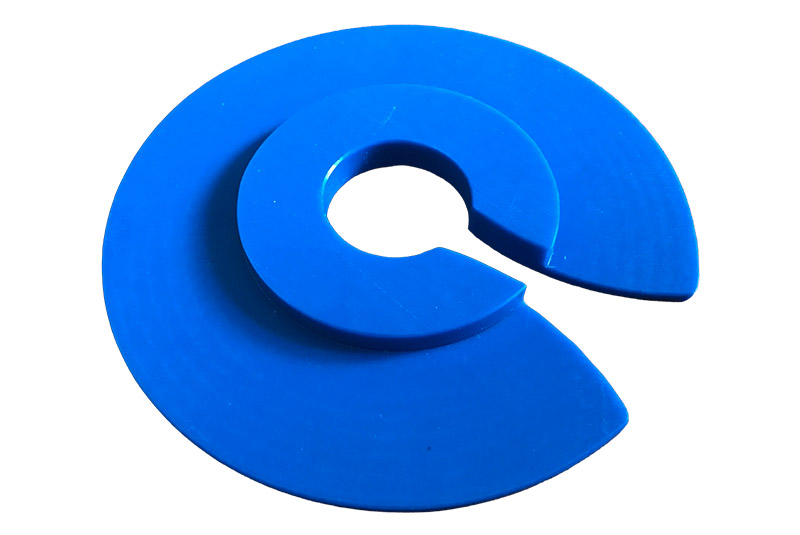

Designed for Fit, Function & Flow

Our CNC service allows precise engineering of parts that improve usability, automation, and ergonomics:

- Ensure compatibility with racking, totes, and systems

- Machine exact slots, ports, or cut-outs for automation

- Reinforce areas without adding weight

- Enable fastening, sealing, or modular connections

- Archive specs for accurate reorders or repeat builds

The result: plastic components that work harder, fit better and deliver smarter handling.