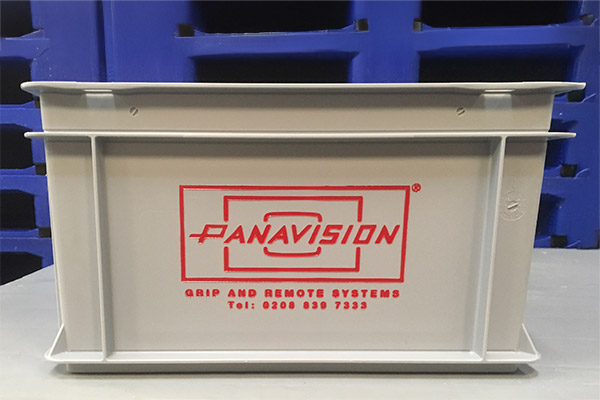

Megafab provides full service CAD design and prototyping for custom plastic containers and handling solutions across the UK and Europe. From first sketches to precision-fit models, we help industrial customers turn ideas into durable, engineered products that perform under real world materials handling conditions.

Our CAD Design & Prototyping Capabilities

Our design team works closely with clients to develop, visualise, and optimise every aspect of a custom crate, pallet, or component. Whether you’re modifying a standard unit or starting from scratch, we turn your requirements into manufacturable, testable designs.

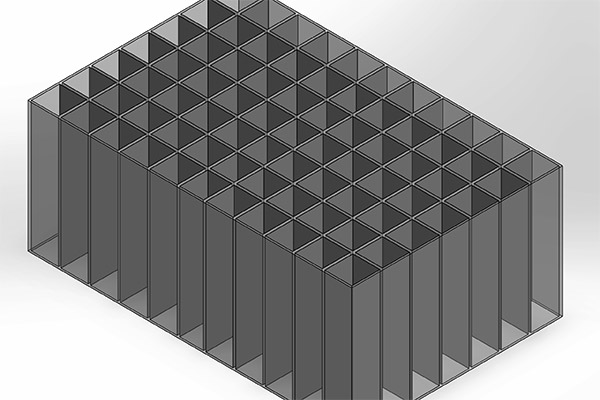

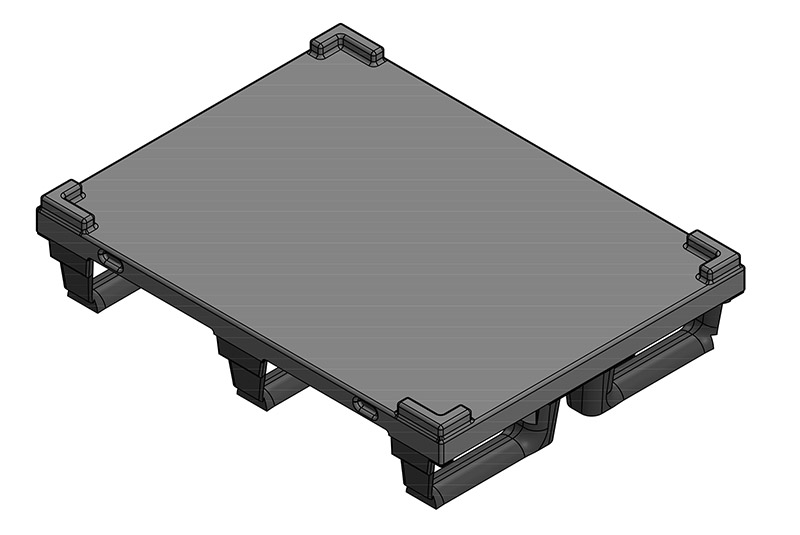

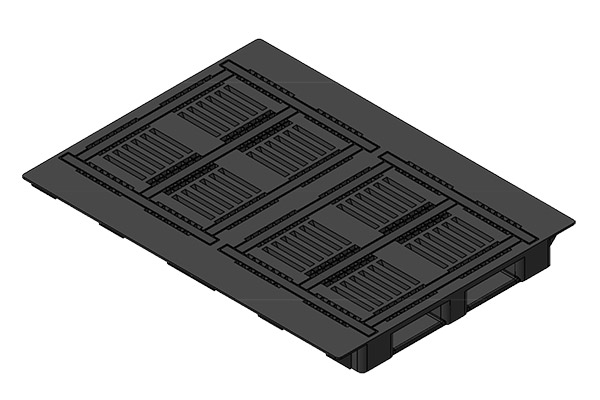

Concept Development & 3D CAD Modelling

Megafab transforms handling problems into tailored solutions using modern CAD software and industrial experience.

- Develop custom designs based on load, process, or environment

- Produce accurate 2D and 3D models for visualisation and review

- Adjust features like dimensions, runners, ports, or closures

- Collaborate on DFM improvements to simplify manufacturing

- Create documentation for approval, scaling, or procurement

Every CAD model is created to match functional goals and reduce risk before production begins.

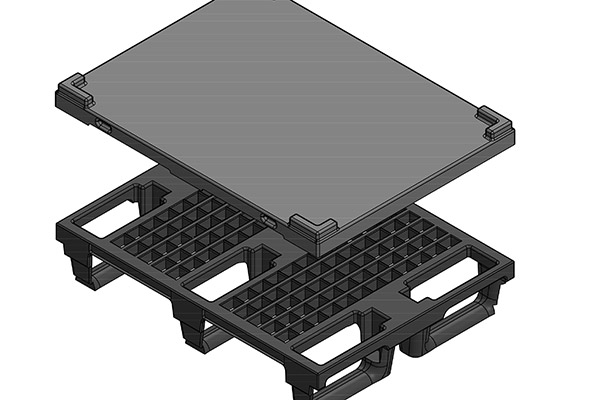

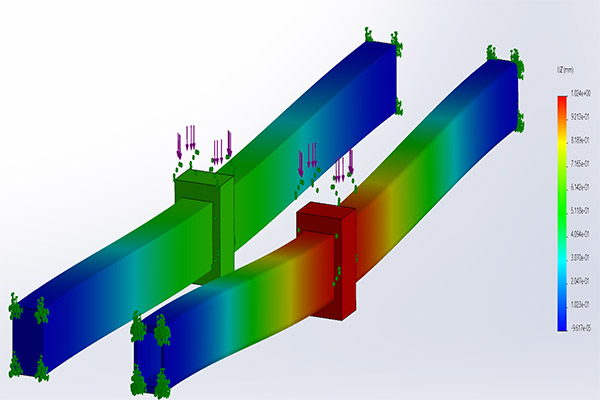

Prototyping for Fit, Function & Testing

We build physical prototypes to validate designs before committing to full fabrication or large volume production.

- Produce full-size or scaled prototypes using stock materials

- Test fit, compatibility, and ergonomic handling features

- Validate performance under load, vibration, or stacking

- Iterate and refine based on testing or user feedback

- Ensure smooth transition to CNC, welding, or full assembly

Prototyping helps catch issues early and ensures every solution works where it matters—on the factory floor.

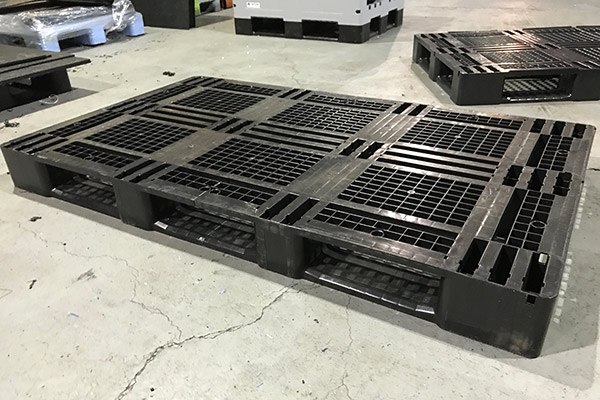

Built for Industrial Use

Our CAD and prototyping work supports clients operating in:

- Materials handling and automation

- Logistics and warehouse operations

- Closed-loop and returnable packaging

- Manufacturing and cleanroom processes

- Engineering, energy, and electronics industries

Each design is grounded in real use cases and engineered for repeatable, reliable performance.

Design Services That Scale With You

Megafab supports projects from first concept through to mass production and long-term supply.

- Quick-turn CAD files for early-stage project scoping

- Full design files for approval and procurement workflows

- Revisions and updates as usage or systems evolve

- Seamless handoff to in-house machining and fabrication

- Digital archives for reliable reordering or scaling

Whether you’re launching a new product or optimising a legacy one, we’ll help you design it right.

Practical Engineering - Real Results

We design with production, function, and field use in mind, balancing innovation with practicality.

- Account for weight limits, movement, and automation

- Align form and function for seamless container handling

- Prioritise manufacturability with minimal waste

- Ensure features work with your workflows and equipment

- Support sustainability with long-life, reusable solutions

Our design approach is grounded in real-world problem-solving—backed by tools, knowledge, and experience.