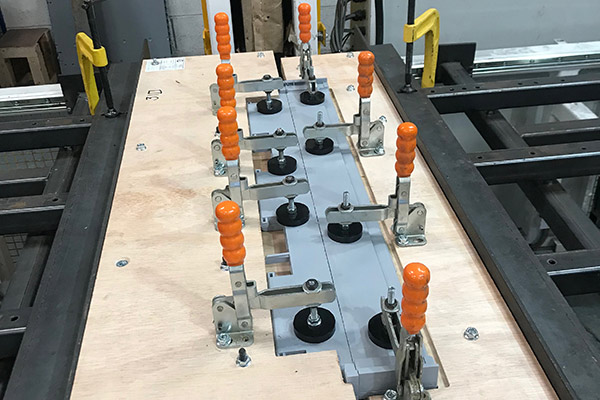

At Megafab, we use precision plastic butt welding to create and customise heavy-duty components for the materials handling industry. This advanced welding process allows us to permanently join plastic sheets and panels, enabling the production of oversized crates, pallets, and storage boxes, as well as tailored modifications to standard units. The result is stronger, more durable, and fully reusable products engineered to your exact needs.

Our Plastic Butt Welding Capabilities

Our in-house butt welding service provides a robust way to adapt and extend plastic products for industrial use. Using specialist machinery, we produce seamless joins that restore or enhance structural integrity.

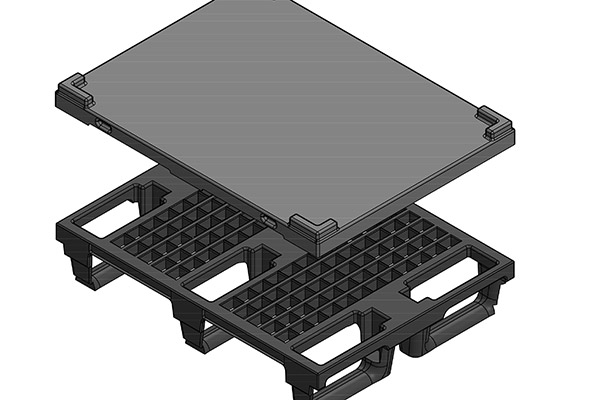

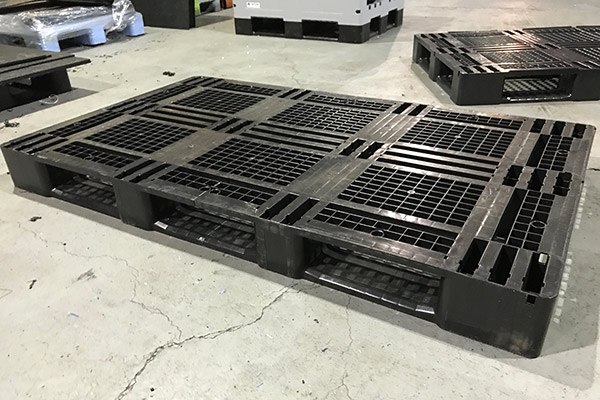

Crates & Pallets

Tailored adjustments for automated handling and bulk transport:

-

Extend dimensions for large-format loads

-

Reinforced joins for heavy-duty applications

-

Structural repairs for damaged units

-

Integration of runners, feet, or bases

-

Anti-slip or textured weld finishes

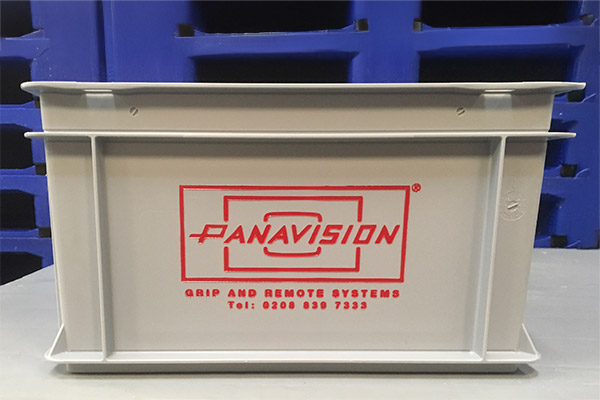

Oversized Storage Boxes

Purpose-built containers for bulky or irregular products:

-

Welded sheets for extended width or height

-

Secure, leak-tight joins for durability

-

Drop-down or hinged door options

-

Internal fittings such as dividers or trays

-

Branding or identification features

Built for Industrial Use

Megafab’s butt welded products are designed for:

-

Automated handling systems

-

Returnable packaging loops

-

Warehousing and closed-loop logistics

-

Manufacturing and assembly plants

-

Recycling and bulk material storage

Whatever your sector, we deliver solutions that combine strength, sustainability, and long-term value.

Scalable Supply for Custom Projects

Our butt welding service isn’t limited to one-off builds — it scales to match your project requirements. From prototypes to full production runs, Megafab delivers consistent quality across every unit.

-

Small batches for trials or new product launches

-

Medium volumes for specialist supply chains

-

High-volume runs for standardised fleets

-

Flexible lead times to meet project deadlines

-

UK-based production for reliable delivery

No matter the project size, you get the same engineered precision and industrial-grade durability.

Engineered Plastics for Form and Function

By combining butt welding with our expertise in engineered plastics, we create products that perform in the toughest environments. Every weld and material choice is made with long-term use in mind.

-

High-strength polymers for heavy-duty loads

-

UV- and chemical-resistant options available

-

Smooth welds for hygiene and easy cleaning

-

Compatible with automated handling systems

-

Custom finishes to meet branding or compliance needs

The result: welded solutions that look professional, function reliably, and withstand demanding industrial applications.